When installing a gymnastic horizontal bar, ensuring proper stability is crucial for athlete safety and performance. The stability of a gymnastic horizontal bar depends on multiple installation factors that work together to create a secure training environment. Professional gymnastics facilities must consider foundation requirements, structural support systems, and precise mounting specifications to achieve optimal stability. Understanding these critical elements helps facility managers make informed decisions about their gymnastic horizontal bar installations and maintain the highest safety standards for their athletes.

Foundation and Floor Requirements

Concrete Foundation Specifications

The foundation serves as the primary support system for any gymnastic horizontal bar installation. A properly constructed concrete foundation must extend at least 36 inches deep and span 8 feet in width to distribute the load effectively. The concrete mixture should achieve a minimum compressive strength of 3,000 PSI to withstand the dynamic forces generated during gymnastic routines. Professional installers recommend using reinforced concrete with steel rebar grids to prevent cracking and ensure long-term structural integrity.

Foundation preparation involves excavating the installation area and creating a level base that accommodates the specific dimensions of the gymnastic horizontal bar system. The foundation must account for frost line requirements in colder climates to prevent heaving and shifting during temperature changes. Proper drainage around the foundation prevents water accumulation that could compromise the concrete integrity over time. Installation teams typically allow 28 days for complete concrete curing before mounting the gymnastic horizontal bar equipment.

Floor Surface Considerations

The floor surface surrounding a gymnastic horizontal bar requires specialized materials that provide both safety and stability. Professional-grade gymnastics flooring systems incorporate multiple layers including foam padding, spring systems, and durable vinyl surfaces. The flooring extends at least 12 feet in all directions from the gymnastic horizontal bar to create adequate landing zones for athletes. Impact-absorbing materials reduce the risk of injury while maintaining the structural stability needed for the equipment mounting points.

Floor installation must account for the additional weight and stress points created by the gymnastic horizontal bar support system. Specialized underlayment materials distribute concentrated loads across larger areas, preventing floor damage and maintaining equipment stability. The flooring system integrates with the foundation to create a unified support structure that enhances overall installation stability. Regular inspection and maintenance of the floor surface ensure continued safety and performance for gymnastic horizontal bar training.

Structural Support Systems

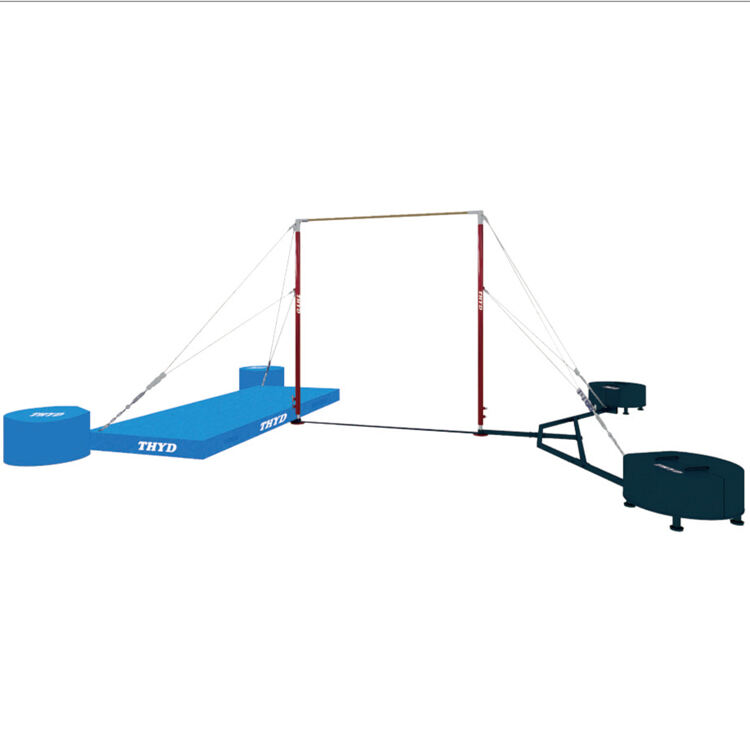

Counterweight Frame Integration

Modern gymnastic horizontal bar installations often incorporate counterweight frame systems that enhance stability and adjust tension automatically. These sophisticated support mechanisms use precisely calibrated weights to maintain consistent bar tension regardless of athlete load or movement intensity. The gymnastic horizontal bar counterweight system requires professional calibration to ensure proper operation and safety compliance. Installation technicians must position counterweight frames according to manufacturer specifications and local building codes.

Counterweight frame systems provide several advantages over traditional fixed-mounting approaches including reduced stress on foundation anchors and improved shock absorption. The mechanical advantage created by counterweight systems allows for more precise tension control and extends the lifespan of both the bar and mounting hardware. Professional installation ensures that counterweight mechanisms operate smoothly and maintain proper balance throughout the full range of gymnastic routines. Regular inspection and adjustment of counterweight systems maintain optimal performance and safety standards.

Cable and Pulley Configuration

Cable and pulley systems in gymnastic horizontal bar installations require precise configuration to maintain proper tension and stability. High-strength aircraft cables rated for gymnastic applications provide reliable support while allowing for necessary flexibility during use. Pulley systems must incorporate sealed bearings and corrosion-resistant materials to ensure smooth operation in gymnasium environments. Professional installation includes proper cable routing and tension adjustment to eliminate slack and maintain consistent support.

The cable configuration directly impacts the stability and safety of the gymnastic horizontal bar system. Installation technicians use specialized tools to achieve precise cable tension measurements and ensure uniform load distribution across all support points. Pulley placement requires careful consideration of load angles and mechanical advantage to optimize system performance. Regular cable inspection and replacement schedules maintain the integrity of the gymnastic horizontal bar support system and prevent equipment failure.

Mounting Hardware and Specifications

Anchor Bolt Requirements

Anchor bolt selection and installation represent critical factors in gymnastic horizontal bar stability and safety. Professional-grade anchor bolts must meet specific load ratings and corrosion resistance standards for gymnasium environments. Installation requires precise drilling depths and hole diameters to ensure proper anchor engagement with the concrete foundation. Torque specifications for anchor bolts follow manufacturer guidelines and building codes to achieve optimal holding power without over-stressing the hardware.

The anchor bolt pattern for gymnastic horizontal bar installations distributes loads across multiple points to prevent localized stress concentrations. Professional installers use specialized measuring tools to ensure accurate bolt spacing and alignment with the equipment mounting brackets. Chemical anchoring systems provide enhanced holding power in challenging installation conditions and offer superior resistance to dynamic loading. Regular inspection of anchor bolts identifies potential loosening or corrosion that could compromise gymnastic horizontal bar stability.

Mounting Bracket Configuration

Mounting brackets serve as the critical interface between the foundation anchors and the gymnastic horizontal bar structure. These precision-engineered components must accommodate the specific geometry and load requirements of each installation. Professional mounting brackets incorporate adjustability features that allow for fine-tuning of bar height and level during installation. The bracket design accounts for thermal expansion and contraction to maintain proper alignment throughout temperature variations.

Installation of mounting brackets requires careful attention to alignment and levelness to ensure optimal gymnastic horizontal bar performance. Precision measuring instruments verify bracket positioning within specified tolerances before final tightening of connection hardware. The bracket-to-anchor interface uses appropriate washers and spacing elements to distribute loads and prevent stress concentrations. Quality mounting brackets include provisions for routine inspection and maintenance access to support long-term gymnastic horizontal bar reliability.

Height and Clearance Specifications

Regulation Height Requirements

Official gymnastic horizontal bar height specifications vary according to competition level and age group requirements. Senior men's competition bars maintain a height of 275 centimeters above the floor surface, while junior and age group categories use proportionally adjusted heights. Installation accuracy within plus or minus 2 centimeters ensures compliance with governing body regulations. Professional installation teams use laser measuring systems to achieve precise height positioning and maintain consistent measurements across the entire bar length.

Height adjustment mechanisms in modern gymnastic horizontal bar systems accommodate multiple user categories and training requirements. Motorized height adjustment systems provide convenient and precise positioning for different skill levels and age groups. The height adjustment range typically spans from 200 to 280 centimeters to accommodate various gymnastic programs. Installation must ensure smooth operation of height adjustment systems while maintaining structural stability at all positions.

Safety Clearance Zones

Adequate clearance zones around gymnastic horizontal bar installations prevent injuries and allow for safe dismount areas. Minimum clearance requirements specify 4 meters of open space in all directions from the bar centerline. Ceiling height clearances must provide at least 8 meters of vertical space above the gymnastic horizontal bar to accommodate high release moves and giants. Installation planning considers potential obstructions including lighting fixtures, ventilation systems, and structural elements.

Safety zone markings on gymnasium floors help athletes and coaches maintain awareness of clearance boundaries during training sessions. The clearance zones extend beyond the immediate landing areas to account for errant dismounts and emergency situations. Installation documentation includes detailed clearance measurements and safety zone layouts for facility management reference. Regular review of clearance zones ensures continued compliance with safety standards as facility configurations change over time.

Load Testing and Safety Verification

Dynamic Load Testing Procedures

Professional gymnastic horizontal bar installations require comprehensive load testing to verify structural integrity and safety compliance. Dynamic load testing simulates the forces generated during actual gymnastic routines including giants, release moves, and dismounts. Testing equipment applies measured forces that exceed normal usage loads by specified safety factors. Load testing protocols follow industry standards and manufacturer specifications to ensure thorough evaluation of system performance.

Load testing procedures include both static and dynamic components to evaluate different aspects of gymnastic horizontal bar stability. Static testing applies sustained loads to verify foundation and mounting system strength under maximum anticipated forces. Dynamic testing uses oscillating and impact loads to simulate routine usage patterns and identify potential fatigue points. Professional testing equipment measures deflection, vibration, and stress distribution throughout the gymnastic horizontal bar system.

Safety Certification Requirements

Safety certification for gymnastic horizontal bar installations involves comprehensive inspection by qualified professionals and compliance verification with applicable standards. Certified inspectors evaluate all aspects of the installation including foundation integrity, mounting hardware condition, and safety clearances. Documentation requirements include detailed inspection reports, load testing results, and compliance certificates. Annual recertification ensures continued safety compliance and identifies maintenance requirements.

Professional certification programs for gymnastic horizontal bar installations establish standardized evaluation criteria and inspector qualifications. Certified installations receive documentation that demonstrates compliance with safety standards and insurance requirements. The certification process includes review of installation procedures, material specifications, and ongoing maintenance protocols. Facility operators rely on safety certifications to demonstrate due diligence in equipment safety and risk management.

Maintenance and Inspection Protocols

Routine Inspection Schedules

Regular inspection schedules for gymnastic horizontal bar installations identify potential safety issues before they become critical problems. Daily visual inspections by facility staff check for obvious signs of damage, looseness, or wear in the bar and support systems. Weekly detailed inspections examine mounting hardware, cables, and counterweight systems for proper operation and adjustment. Monthly professional inspections provide comprehensive evaluation of all system components and structural elements.

Inspection protocols document specific checkpoints and acceptance criteria for each component of the gymnastic horizontal bar installation. Trained inspectors use specialized tools and measuring equipment to evaluate component condition and performance parameters. Inspection records maintain historical data that tracks system performance trends and identifies patterns that may indicate developing problems. Systematic inspection approaches ensure comprehensive coverage of all safety-critical elements in gymnastic horizontal bar installations.

Preventive Maintenance Programs

Preventive maintenance programs for gymnastic horizontal bar installations extend equipment lifespan and maintain optimal safety performance. Scheduled maintenance activities include lubrication of moving components, tightening of hardware connections, and replacement of wear items according to manufacturer recommendations. Professional maintenance technicians use specialized tools and genuine replacement parts to ensure proper system operation. Maintenance scheduling considers usage intensity and environmental factors that affect equipment condition.

Comprehensive maintenance programs include detailed procedures for each component of the gymnastic horizontal bar system and establish clear responsibility assignments. Maintenance documentation tracks completed activities and schedules future service requirements to prevent oversight of critical maintenance tasks. Professional maintenance contracts provide access to specialized expertise and ensure compliance with manufacturer warranty requirements. Effective preventive maintenance significantly reduces the risk of equipment failure and extends the service life of gymnastic horizontal bar installations.

FAQ

How deep should the foundation be for a gymnastic horizontal bar installation

The foundation for a gymnastic horizontal bar installation should extend at least 36 inches deep to provide adequate stability and load distribution. The depth may need to increase in areas with deep frost lines or challenging soil conditions. Professional installers evaluate site-specific conditions including soil composition, drainage, and local building codes to determine optimal foundation depth. A properly constructed foundation ensures long-term stability and prevents shifting or settling that could compromise equipment safety.

What safety clearances are required around a gymnastic horizontal bar

Safety clearances around a gymnastic horizontal bar require a minimum of 4 meters of open space in all horizontal directions from the bar centerline. Vertical clearance must provide at least 8 meters of height above the bar to accommodate high-flying elements and release moves. Additional clearance may be required based on the skill level of athletes using the equipment and specific facility safety protocols. Proper clearance zones prevent collisions with walls, equipment, or other obstacles during training and competition.

How often should a gymnastic horizontal bar undergo professional inspection

Professional inspection of a gymnastic horizontal bar installation should occur monthly during periods of regular use, with comprehensive annual inspections by certified technicians. High-usage facilities may require more frequent professional inspections to ensure continued safety compliance. Daily visual inspections by facility staff supplement professional inspections and identify obvious problems that require immediate attention. Regular inspection schedules help prevent equipment failures and maintain safe training conditions for athletes.

What are the main components of a counterweight system for gymnastic horizontal bars

A counterweight system for gymnastic horizontal bars includes calibrated weights, cable systems, pulleys, and adjustment mechanisms that automatically maintain proper bar tension. The counterweight frame provides structural support and houses the mechanical components that balance the system loads. Professional installation ensures proper calibration and smooth operation of all counterweight system components. These systems reduce stress on foundation anchors while providing consistent performance across varying load conditions during gymnastic routines.

Table of Contents

- Foundation and Floor Requirements

- Structural Support Systems

- Mounting Hardware and Specifications

- Height and Clearance Specifications

- Load Testing and Safety Verification

- Maintenance and Inspection Protocols

-

FAQ

- How deep should the foundation be for a gymnastic horizontal bar installation

- What safety clearances are required around a gymnastic horizontal bar

- How often should a gymnastic horizontal bar undergo professional inspection

- What are the main components of a counterweight system for gymnastic horizontal bars